PLASTER MOLDING OF THE WAX PATTERNS.

The mold mix is one kg of gypsum, one kg of silicon flour to one liter of water.

The initial film of plaster flowed over surface with attention to removing trapped air bubbles.

Multi pours before the plaster sets, building up a thick layer.

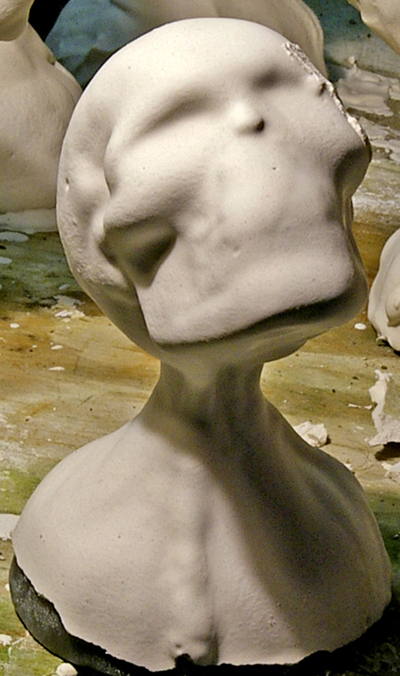

The wax skull now covered with the all important pre coat of the molding plaster. Extreme care with this initial application eliminates air bubbles caught on the sticky wax surface which will prevent much extra work in the final cleaning up of the cast lead crystal skull.

A taped up container to hold the liquid plaster is of made from printers plates, pressed into a bed of soft clay.

The wax Skull fully invested in plaster…….

and now ready to steam out the wax.